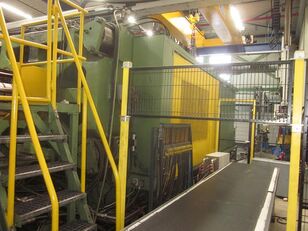

Fritsch placeALL 510 with Conveyor injection moulding machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

Manufacturer

Fritsch

Model

placeALL 510 with Conveyor

Condition

used

Operating Time

2387 h

1-piece machine frame

50 feeder positions for 8mm tape

2 feeder racks with 25 slots for tape/tube feeders

On-the-fly laser centering with Cyberoptics for chips from size 0402 to BE 32x32mm

Component waste function

LED placement area lighting

2 dispensers – Time/pressure system including Martin control unit

Teach-in camera for alignment of

positions and quality control

Conveyor width adjustable in steps to approximately 300mm

Vision camera and lighting

Suitable for placing fine-pitch components and custom forms (up to 0.4mm pitch) and chips (0402

BT max. 48x48mm)

Evaluation of all pins (available

straight) and software calculates correction factor for precise placement

Automatic reference mark recognition

Universal CAD conversion/import of data from any CAD format

Vacuum membrane pump (quiet external pump with 30l/min suction capacity)

Find more here

show contacts

Contact us at

show contacts